|

|

|

|

jeremy11

Mar 25, 2010, 11:07 PM

Post #1 of 19

(25263 views)

Shortcut

Registered: May 28, 2004

Posts: 597

|

This fall I began to develop my ideas for this year's homemade cam.

As an offwidth climber, the choice was obvious. Go Big.

One of Tom Kasper's comments on big cam weight reduction stuck out to me: minimize steel.

With that in mind, I got to thinking. How well would an over-sized hollow steel axle work? Big cams have space for such experiments.

Or even, how would an over-sized solid aluminum axle hold up?

I did some thinking on a Y-stem, hoping to get the leverage reducing benefits of the U-stem with the walk reducing benefits of a single stem. And, hoping to get innovation points even if the idea is silly.

After purchasing a swaging tool and some materials, I made a test Y stem, only to realize that there was simply not space to crimp the cable stops around the aluminum pieces pictured above. Furthermore, I realized that the Y-stem was primarily a stunt to get innovation points.

Then another Idea, on a user friendly way to carry the cam with the lobes shut (like the stick trick) and quickly open it, required the use of a U-stem.

Prototyping this component took some some fancy jigsawing and needle filing, then ended up not being the way to go.

Simply not smooth enough action, and not enough space on the spacer bar. It was also unnecessarily complex. There is a better way.

Unsure of my solid aluminum axle idea and alloy selection, as well as cable selection and swaging, I decided to make up a proof of concept cam to break. The primary concern was the shear strength of the axle, especially as harder alloys sometimes tend to be more brittle.

A brief pull testing video:

http://www.youtube.com/watch?v=jbkZDCuNTxQ

We broke 6mm, 7mm, 8mm, and 1" webbing single strand fuses with the cam holding just fine.

Then we put in a 7mm loop, and a piece of rock broke and the cam pulled out. The lobes were bent, and the cable was mangled. So we put the cam into a constriction, and managed to break the 7mm loop. This was all the Jeep could do, with snow on the road, so we broke a couple old retired harnesses and packed up. Very Fun.

This puts the strength of the cam at at least 14 kN

The axle was unmarred.

On to the real thing.....

|

|

|

|

|

johnwesely

Mar 25, 2010, 11:13 PM

Post #2 of 19

(25260 views)

Shortcut

Registered: Jun 13, 2006

Posts: 5360

|

Super cool write up.

Thanks.

|

|

|

|

|

hafilax

Mar 25, 2010, 11:19 PM

Post #3 of 19

(25256 views)

Shortcut

Registered: Dec 12, 2007

Posts: 3025

|

How much lighter is the aluminum axle than a conventional steel axle?

|

|

|

|

|

jeremy11

Mar 25, 2010, 11:39 PM

Post #4 of 19

(25242 views)

Shortcut

Registered: May 28, 2004

Posts: 597

|

With Inspiration from rschap's Web Cam, I began work on the second set of lobes.

A little drawing, a bit of jigsawing, and a lot of filing,

dremeling, needle filing, and sanding later, and some lobes popped off the assembly line.

My little niece thought it looked like a butterfly:

I was surprised at how 3 items with the same published diameters didn't fit. The axle, the tubing spacer that goes around the axle in the middle and the drill bit didn't match. So, some reaming, rat tail filing, and sanding, and a bit of frustration got them all to fit. The lobes still lose a bit of smoothness to this....

The tools were often challenging as well, and even required hand fabricated set screws to keep the belt and pulleys from falling off.....

A bottle opener was added in for curb appeal, even though I don't have need of them personally:

It seemed doubly appropriate on an offwith cam....

Some might like to hydrate before embracing the pain.

Stem #1 came out ok, but needed some refinement

It wasn't smooth enough, was a couple inches too long, and could use a better machined trigger bar and spacer.

After whipping up Stem #2, I could finish final assembly.

1 pound, 14 ounces.

Since the axle was unmarred after holding at least a 14 kN load, that means it could potentially be made lighter. I don't currently have the know how to design or machine that.

The Valley Giant #9 is 1 pound 15 ounces. Although some of that could be from my ridiculous lobe machining.

All in all, much better than last year's joke

Cleaveland Mountaineering would like to thank Adatesman, Tom Kasper, Ray Jardine, and all the other handmade cam craftsmen for inspiration and education.

A special thanks to Steve N and Ryan J for design help, pull testing help, brainstorming ideas (letting me talk their ears off with technobabble) and for allowing me to drag them up a bunch of grungy offwidths.

With this beast around now, hopefully I can restrain myself.

|

|

|

|

|

jeremy11

Mar 25, 2010, 11:41 PM

Post #5 of 19

(25240 views)

Shortcut

Registered: May 28, 2004

Posts: 597

|

Oops, forgot specs:

Range: 8.5"-5.5" guesstimate, I'll need to measure it for real.

Axle width: 4"

I might also whip up some 1/4" shaft collars instead of those monstrous 1/2" shaft collars. It would save about an ounce, but I really don't feel like it.

Also, at Steve N's recommendation, I cut the Black Diamond logo off the sling, so the boys at the climbing gym won't get confused.

(This post was edited by jeremy11 on Mar 25, 2010, 11:47 PM)

|

|

|

|

|

kennoyce

Mar 26, 2010, 1:35 AM

Post #6 of 19

(25159 views)

Shortcut

Registered: Mar 6, 2001

Posts: 1338

|

That looks awesome. Nice job! The one thing I would worry about is buckling of the lobes. You might want to test that one as well (maybe just to 8 or 10 kN) before climbing on it since you did take a lot of aluminum out of the lobes.

All in all nice work. I have also thought of some similar ways to eliminate weight in the axle of a large cam, but alas I have not yet had time to build one. Maybe this summer.

|

|

|

|

|

patto

Mar 26, 2010, 1:38 AM

Post #7 of 19

(25157 views)

Shortcut

Registered: Nov 15, 2005

Posts: 1453

|

jeremy11 wrote: I did some thinking on a Y-stem, hoping to get the leverage reducing benefits of the U-stem with the walk reducing benefits of a single stem.

I'm sorry what 'leverage reducing benefits of the U-stem'? U stem increases leverage on the cam head (the torque). This is the severe issue with U stems and why I generally avoid them.

|

|

|

|

|

jeremy11

Mar 26, 2010, 3:06 PM

Post #8 of 19

(25063 views)

Shortcut

Registered: May 28, 2004

Posts: 597

|

patto wrote: jeremy11 wrote: I did some thinking on a Y-stem, hoping to get the leverage reducing benefits of the U-stem with the walk reducing benefits of a single stem. I'm sorry what 'leverage reducing benefits of the U-stem'? U stem increases leverage on the cam head (the torque). This is the severe issue with U stems and why I generally avoid them.

Sounds like you are referring to the stability of the axle, and the U-stem twists it easier.

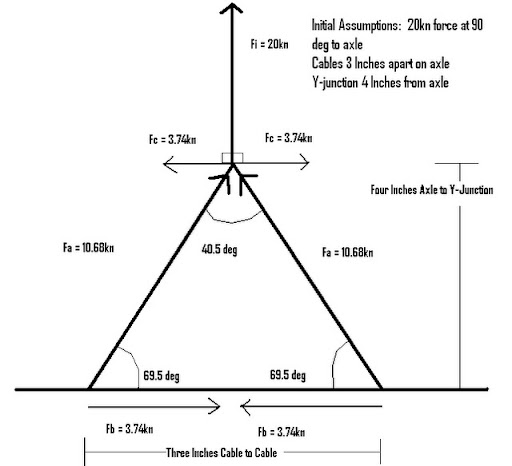

I'm referring to the likelyhood of the axle to bend. The U-stem places the force closer to the lobes, so instead of one cable 1 or more inches from the inside lobes, we place 2 cables (with half the force in each) as close to the lobes as possible. Moment = Force * Distance, so we cut the force in half, spreading it over both cables, and greatly decreased the distance. This helps the axle not bend.

I did some volume and density calculations last night, looks like my Al axle weights twice as much as a 3/8"*4.5" steel axle.

This isn't really too surprising, but I hadn't broken it down to numbers before.

This was the smallest diameter available for the alloy I chose for the axle.

I don't know yet how to make the jump from what forces are felt where to picking the best, lightest setup for the job. Not sure how an Al axle would hold up, I went with overkill.

With a lathe, or hollow tubing in the right alloy, I could get the weight to match that of a steel axle, but I'd need to hollow out the axle to 1/8" thick walls, and besides not having the tooling to do this, I also have no idea if it would be strong enough or if the tubing would collapse.

That is all just to get the weight to match that of a steel axle.

I had a hunch the whole time that steel was better, but wanted to make sure.

Pull testing was sure fun!

|

|

|

|

|

philbox

philbox

Moderator

May 2, 2010, 11:15 AM

Post #9 of 19

(24556 views)

Shortcut

Registered: Jun 27, 2002

Posts: 13105

|

I think that what you may have inadvertantly done is to solve the problem of sideways deformation of large cams with your large sized axle. Seems to me that the sideways bending moment would be lessened by way of a large diameter axle.

So an extremely large axle should increase stability of the cam lobes. In other words if we were to go to extremes and produce a cam with an axle of 5 inch diamter for a minimum collapsed cam width of 5.5 inches then surely that would be a mega stable sideways loadable cam.

|

|

|

|

|

jeremy11

May 2, 2010, 7:14 PM

Post #10 of 19

(24424 views)

Shortcut

Registered: May 28, 2004

Posts: 597

|

philbox wrote: I think that what you may have inadvertantly done is to solve the problem of sideways deformation of large cams with your large sized axle. Seems to me that the sideways bending moment would be lessened by way of a large diameter axle. So an extremely large axle should increase stability of the cam lobes. In other words if we were to go to extremes and produce a cam with an axle of 5 inch diamter for a minimum collapsed cam width of 5.5 inches then surely that would be a mega stable sideways loadable cam.

That was one thought behind it. On the test cam the lobes still bent. While playing with it I put Al spacers in between the lobes (1.25") which really helped reduce the sideways motion of the lobes, but I couldn't get springs wound that big, or figure out how to keep the spring from jamming between the lobes and spacer.

My #5 WC Friend looks like there is an extension of the lobe at the axle. Since they already have machined cam lobes, this is an easy addition that should really reinforce this area.

Valley Giants I think have a spacer between the lobes, and was the inspiration for my test. But a spacer around a 3/8" axle is smaller, and easier to wind springs for than a 1.25" spacer.

My lobes are also more wobbly than necessary since the 3/4" drill bit was just a little bit smaller than the 3/4" axle, so I had to sand out the axle holes in the lobes to get it to fit, and inaccuracies in the sanding made the lobes looser and less smooth than I wished for. Perhaps another factor is that both the lobes and axle are Al. In my limited knowledge of bushings, one material should be softer than the other.

|

|

|

|

|

Rudmin

May 3, 2010, 2:55 PM

Post #11 of 19

(24320 views)

Shortcut

Registered: Mar 29, 2009

Posts: 606

|

jeremy11 wrote: My lobes are also more wobbly than necessary since the 3/4" drill bit was just a little bit smaller than the 3/4" axle, so I had to sand out the axle holes in the lobes to get it to fit, and inaccuracies in the sanding made the lobes looser and less smooth than I wished for. Perhaps another factor is that both the lobes and axle are Al. In my limited knowledge of bushings, one material should be softer than the other.

Shouldn't they not both be aluminum also?

|

|

|

|

|

jeremy11

May 3, 2010, 3:02 PM

Post #12 of 19

(24313 views)

Shortcut

Registered: May 28, 2004

Posts: 597

|

both axle and lobes are aluminum

|

|

|

|

|

Rudmin

May 3, 2010, 3:05 PM

Post #13 of 19

(24309 views)

Shortcut

Registered: Mar 29, 2009

Posts: 606

|

jeremy11 wrote: both axle and lobes are aluminum

|

|

|

|

|

jeremy11

May 3, 2010, 3:25 PM

Post #14 of 19

(24284 views)

Shortcut

Registered: May 28, 2004

Posts: 597

|

Got it.

Already mentioned that:

jeremy11 wrote: Perhaps another factor is that both the lobes and axle are Al. In my limited knowledge of bushings, one material should be softer than the other.

Are you referring to seizing from corrosion, or just not being as smooth of a pull?

Maybe it could use a brass bushing?

Another thought I had was to make a hollow Al axle, then have a thin tube of steel around it, both for smoothness, and some more strength.

Or, just get a steel axle like everybody else!

Or a slightly oversized, hollow steel axle - oversized to reduce lobe wobble, hollow to keep the weight the same as a standard axle. But you can't go too thin with the tubing wall thickness, or it could collapse.

(I did think about drilling the lobes out bigger and pressing in sealed ball bearings, but figured that is a solution that would just cause more problems - weight, cost, strength.....)

|

|

|

|

|

Rudmin

May 3, 2010, 4:12 PM

Post #15 of 19

(24237 views)

Shortcut

Registered: Mar 29, 2009

Posts: 606

|

jeremy11 wrote: Got it. Already mentioned that: jeremy11 wrote: Perhaps another factor is that both the lobes and axle are Al. In my limited knowledge of bushings, one material should be softer than the other. Are you referring to seizing from corrosion, or just not being as smooth of a pull? Maybe it could use a brass bushing? Another thought I had was to make a hollow Al axle, then have a thin tube of steel around it, both for smoothness, and some more strength. Or, just get a steel axle like everybody else!  Or a slightly oversized, hollow steel axle - oversized to reduce lobe wobble, hollow to keep the weight the same as a standard axle. But you can't go too thin with the tubing wall thickness, or it could collapse. (I did think about drilling the lobes out bigger and pressing in sealed ball bearings, but figured that is a solution that would just cause more problems - weight, cost, strength.....)

Bearings would be pretty sweet, but you would have some massive bearings weighing about 4 lbs (for 4 of them) if you wanted them to be rated for the kind of loads they would be seeing. Bearings don't take static loads well I think because the BBs indent the races when they are in one spot and you push hard on them.

|

|

|

|

|

drector

drector

May 3, 2010, 4:48 PM

Post #16 of 19

(24208 views)

Shortcut

Registered: Aug 27, 2002

Posts: 1037

|

"Bearings" doesn't automatically imply ball bearings.

|

|

|

|

|

bill413

May 3, 2010, 4:55 PM

Post #17 of 19

(24197 views)

Shortcut

Registered: Oct 19, 2004

Posts: 5674

|

Your niece is right - the finished product does look like a butterfly.

Nice writeup.

|

|

|

|

|

jeremy11

Feb 11, 2012, 3:26 AM

Post #18 of 19

(21943 views)

Shortcut

Registered: May 28, 2004

Posts: 597

|

well, between a running overuse injury, school, and being too much of a pansy for climbing, the monster cam hasn't gotten much use. back in November a few friends and I got together out in Moab for a bit of climbing... they climbed for the week, I had to go back for more enginerd school.

I managed to use it while bailing on a Jim Beyer offwidth at Wallstreet - Right Side In. The crack was hard and squirmy, but the spot that made me whimper and bail was when the crack ended right near the top.

It sure was nice having a huge cam to pull on though...

then R and B hauled it all the way up Castleton Tower

We even conned B into taking a few test whippers (with a TR backup) on this homemade #3 cam

It held fine. It held fine.

(This post was edited by jeremy11 on Feb 11, 2012, 3:28 AM)

|

|

|

|

|

billcoe_

May 1, 2012, 3:42 AM

Post #19 of 19

(21138 views)

Shortcut

Registered: Jun 30, 2002

Posts: 4694

|

So Awesome! Thanks

|

|

|

|

|

|